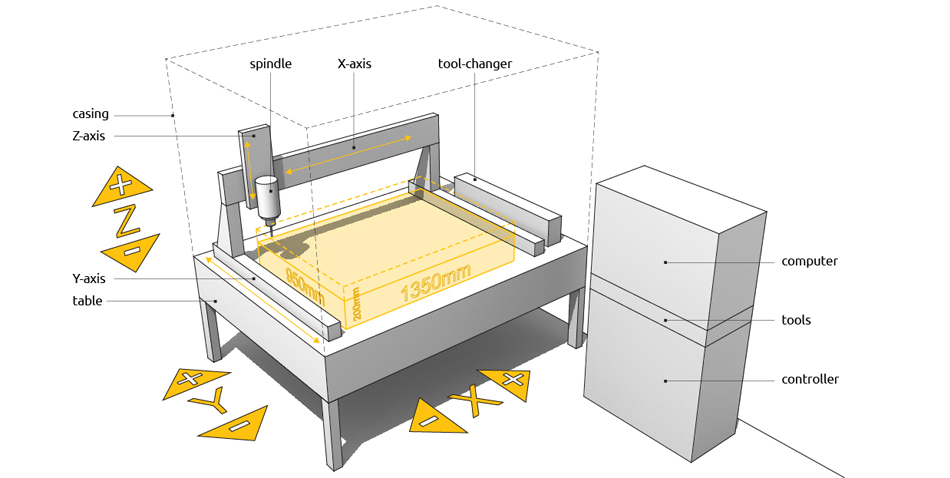

ISEL 3 Axis CNC Milling Machine

CNC Milling Machine

CNC Milling Machine

Post Processor file to be used :

Date : 23/03/2022 ISEL-IOA

Date : 30/03/2022 ISEL-IOA

Date : 20/05/2022 ISEL-IOA

Materials:

- modelling/tooling boards (Sika, or similar..)

- styrofoam

Machine Data:

- WORKAREA X1400 x Y1000 x Z (300-length of cutting tool) mm

(1350 x 950 x 200 mm is recommended) - SPINDLE-SPEED max. 8000 rpm

- TOOLS each of the 3 design studio manages its own collection.

- Toolholders for cutting tools with various end-diameters are available

Convenient Software Toolchains:

- Rhinoceros 3d (.3dm) -> RhinoCam (.3dm) -> Postprocessor (.iso) -> OWEIN (.ncp) -> Remote

- Maya / 3D Studio Max (.stl .iges .step .dxf …) -> VisualMILL -> Postprocessor (.iso) -> OWEIN (.ncp) -> Remote

Preproduction:

IN GENERAL: NO ONE WHO HASN’T TAKEN THE CNC-Technologies Course by Ivan Tochev is allowed to use this milling machine!

All indroduced students will find some more advice on how to prepare your geometry for milling and on how to set up files on these webpages:

http://makezine.com/magazine/cnc-routing-basics-toolpaths-and-feeds-n-speeds/

http://lcamtuf.coredump.cx/gcnc/full/

Older software as RhinoCAM is not recommended as the error rates are much higher especially as CNC-Milling is a process that can cause severe injuries if not properly handled!

Production:

The use of the ISEL CNC-Milling Machine is only allowed with attendance to and proper introduction given in the CNC- Computer Numeric Control – Seminar!

No tutorials in print or on this webpage on how to use the machine are given and the knowledge needs to be transferred in person and a couple of times under surveillance to learn the whole process.

While checking the milling jobs and taking care that the chips and the dust are regularly vacuumed away while processing the file make sure to always wear a breathing mask and safety-goggles and keep the lid of the machine closed while the spindle is in operation.

Postproduction:

After finishing the milling-job please clean the machine and the space around it as properly as possible from all the chips and dust…especially an accumulation of dust over several milling jobs is not good for anyone’s lungs!

Make sure that there is enough room in the bags of the vacuums before starting to clean.

Turn off the computer, controller and the machine (and in case it is still running, also the vacuum).

Put all the toolholder and tools back where they belong.

In short: Please leave the room cleaner than you found it! And everyone will be very grateful for that! 🙂